Products for ferrous metallurgy

Steel Industry is the biggest consumer of the basic refractory

products. Product portfolio for this sector includes the line of

magnesia, magnesia-chromite and magnesia-carbon shaped products-bricks.

According customers needs are the bricks supplemented by the

unshaped products-ramming mixes, gunning mixes, filling mixes,

repairing mixes and mortars. The products are used in safety and

working lining of oxygen converters, electric arc furnaces, ladles and

vessels of secondary metallurgy.

For more information contact marketing department.

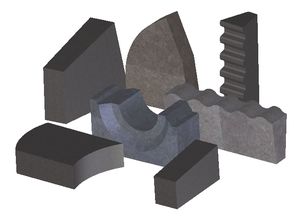

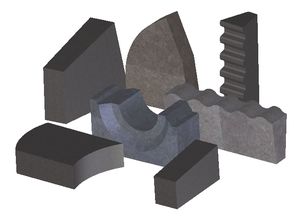

Selected shaped products:

SLI

SLI

Magnesia brick on natural iron magnesia basis

SLID

Magnesia brick on natural iron magnesia basis.

SLIH

High-dense magnesia brick on natural iron magnesia basis.

SLIIIKDT

Direct bonded magnesia-chromite brick with increased resistance to effects of furnace atmosphere.

SFG

Magnesia-chromite brick on fused MCr spinel basis.

SMAG R10F9

Resin bonded magnesia-carbon brick made of fused magnesia with natural graphite content.

SMAG R12F7A

Resin bonded magnesia-carbon brick made of fused magnesia with natural graphite content and with antioxidant.

New magnesia-carbon bricks (Carbores bonded):

SMAG C10F9

Carbores bonded magnesia-carbon brick made of fused magnesia with natural flake graphite content.

SMAG C14F1A

Carbores bonded magnesia-carbon brick made of high quality large crystal fused magnesia, natural flake graphite, with antioxidant.

SMAG C5A15SF24

Carbores bonded magnesia-alumina-carbon brick based on fused and dead-burned magnesia with natural flake graphite content.

Selected unshaped products:

REGUNIT TC60

The basic unshaped product - gunning mass on natural sintered magnesia basis.

REFRAMIT PC70

Dry ramming mass made of iron sintered magnesia with increased CaO content.

REFIX MCZ30

The basic unshaped product - bricklaying mortar made of sintered iron free magnesia.

Products for Steel slag treatment

Rentability of steel production and output of melting aggregates are affected by refractory lining's resistance

(mechanical and thermal shocks) as well as by aggressive chemical influence of slag. It's assumed that chemical

corrosion

of lining is approximately 70 % of total lining's wearing.

FLUXMAG F

The basic additive for treatment of steel slags chemical composition.

References

| Austria: |

MAGNOLITHE GmbH., St. Lorenzen |

|

VOESTALPINE STAHL GmbH., Linz |

| Slovakia: |

ŽELEZIARNE Podbrezová |

| Czech Republic: |

ARCELORMITTAL OSTRAVA A.S. |

|

EVRAZ VÍTKOVICE STEEL, a.s., Ostrava |

|

VÍTKOVICE HEAVY MACHINERY a.s., Vítkovice |

|

POLDI HÜTTE S.R.O., KLADNO

|

|

TŘINECKÉ ŽELEZÁRNY, a.s., Třinec |

|

ČKD KUTNÁ HORA, a.s., Kutná Hora |

|

SCB FOUNDRY, a.s., České Budějovice |

| Germany: |

HűTTENWERKE KRUPP MANNESMANN GmbH. |

|

THYSSENKRUPP STEEL A.G. |

| Italy: |

THYSSENKRUPP TERNI, Terni |

| USA: |

NORTH AMERICAN REFRACTORIES |

Products for non-ferrous metallurgy

Bricks and mortars for copper, lead, zinc and nickel heat aggregates production.

They can be used in anode furnaces, converters, drum furnaces,

flash smelting furnaces, etc.

For more information contact marketing department.

Selected shaped products:

SLV30D

SLV30D

High burned magnesia-chromite brick with direct bond

SLV40NZ

Magnesia-chromite brick with direct bond

STF

Magnesia-chromite brick on fused MCr spinel basis

SLIIID

Magnesia-chromite brick

SLIIIDB

Magnesia-chromite brick with fused MCr spinel content.

SLIIIKTZ

High-dense magnesia-chromite brick with direct bond.

Selected unshaped products:

REFIX MCZ30

Basic unshaped product - bricklaying mortar on sintered iron free magnesia basis.

REGUNIT TC60

Basic unshaped product - gunning mass on natural sintered magnesia basis.

References

| |

|

| Germany: |

ELEKTROWERK WEISSWEILER GmbH., Eschweiler-Weisweiler |

Peru: |

CONSORCIO METALÚRGICO S.A., Lima |

| Italy: |

PIOMBIFERA ITALIANA SpA., Maclodio

|

| Poland: |

RZEŁ BIAŁY S.A., Piekary Śląskie |

|

KGHM POLSKA MIEDŹ S.A. Oddział Huta Miedzi „Głogów" |

|

KGHM POLSKA MIEDŹ S.A. Oddział Huta Miedzi „Legnica" |

Products for cement industry

Products for this sector enable to adjust linings for certain conditions,

temperature zones and according to thermal zones and rotary kiln diameter. Bricks

for this purpose have generally one side sheeting with dilatation carton and colour code.

For more information contact marketing department.

Selected shaped products:

SLIMA20

SLIMA20

Magnesia–spinel brick on iron sintered magnesia and fused MA spinel basis with good mechanical and thermal shocks resistance

SLIMA86AF

Magnesia-spinel brick on pure magnesia basis for extra difficult production conditions.

SLIMA85ZR

Magnesia-spinel brick on high pure magnesia basis with ZrO2 content.

SLIMA82

Magnesia-spinel brick resistant to thermal, mechanical and chemical impacts.

SLIFORM

Magnesia-forsterite brick.

SLIIC5A

Magnesia-chromite brick with increased thermal shocks resistance.

SLIIIV

High burnt magnesia-chromite brick with direct bond.

Selected unshaped products:

REFIX MSZ23

Basic unshaped product–mortar on sintered magnesia and chrome ore basis.

REFIX MCZ10

Basic unshaped product - bricklaying mortar on natural iron sintered magnesia basis.

References

| Republic of Belarus: |

KRASNOSELSK Cement, Krasnoselsk |

| Czech Republic: |

ČMC MOKRÁ A.S., Brno - Přízřenice |

|

ČMC A.S Radotín |

|

CEMENT HRANICE, a.s. Hranice |

|

LAFARGE CEMENT, Čížkovice |

| Italia: |

BUZZI UNICEM SpA, Monferrato |

| Poland: |

DYCKERHOFF POLSKA Sp. z o.o., Nowiny |

| Slovakia: |

POVAŽSKÁ CEMENTÁREŇ A.S. Ladce |

| Slovenia: |

SALONIT ANHOVO, D.D. Deskle |

| Syrian Arab Republic: |

CEMENT Hamma |

Products for lime industry

Basic refractory products for this segment are available in rotary and shaft kilns.

Various shapes and quality enables to make linings for particular thermal zones and

technological conditions.

For more information contact marketing department.

Selected shaped products:

SLIMA10

SLIMA10

Magnesia-spinel brick with increased resistance to chmeical effect of cement sinter.

SLIMA20

Magnesia-spinel brick on iron sintered magnesia and MA spinel basis.

SLIMA90

Magnesia–spinel brick on low-iron basis with chemical impact resistance, for extra stressed parts of linings.

SLIMAAS90

Magnesia–spinel brick with low Al

2O

3 content.

SLIIC5A

Magnesia-chromite brick with high thermal resistance.

SLIIIC

Magnesia-chromite brick with increased thermal shocks resistance.

Selected mortars:

REFIX MCZ10

REFIX MCZ10

Basic unshaped product–mortar on sintered natural iron magnesia basis.

REFIX MCZ30

Basic unshaped product–mortar on sintered iron free magnesia basis.

References

| Slovakia: |

DOLVAP, s.r.o. Varín |

|

BUKOCEL, a.s. Vranov |

| Czech Republic: |

LHOIST Vápenka Čertovy schody a.s. |

Ukraine: |

METALLURGICHESKIJ KOMBINAT AZOVSTAL, OAO, Mariupol |

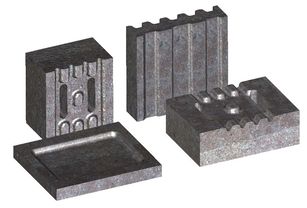

Products for Storage Heaters

A high specific heat capacity of magnesia can be utilized in block storage heaters production

for a heat accumulation until its effective consumption.

Variously shaped products on basis of sintered magnesia and olivine can be used.

Various shaped products on sintered magnesia and olivine basis.

Selected shaped products:

SLIW

Magnesia brick on sintered magnesia basis.

SLIWA

Magnesia-forsterite brick on olivine basis.

For more information contact marketing department.

References

| Germany: |

ROOS GmbH ELEKTROHEIZGERÄTE, Boppard |

|

GLEN DIMPLEX DEUTCHLAND GmBH., Kulmbach |

|

SCHüRER-BENZ HEIZSYSTEME GmbH., Kirchheim |

| Serbia: |

MAGNOFETP DOO KRALJEVO, Kraljevo |

| Poland: |

INPROEL-3 SP. Z O.O., Inowrocław |

SLI

SLI